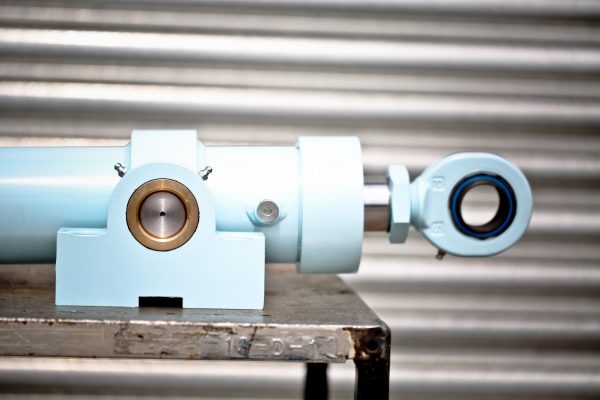

Benefits

- Cost effective

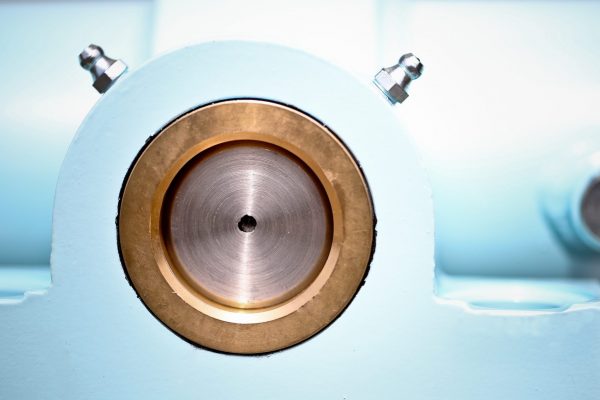

- Avoid corrosion in the tube bore as the cylinder is filled with oil

Disadvantages

- Only works in extension

- Extension force is less than single acting cylinders of the same size

- Less control than double acting cylinders

- Limited range of hydraulic valves can be used with the cylinder

- Requires external force to retract the cylinder