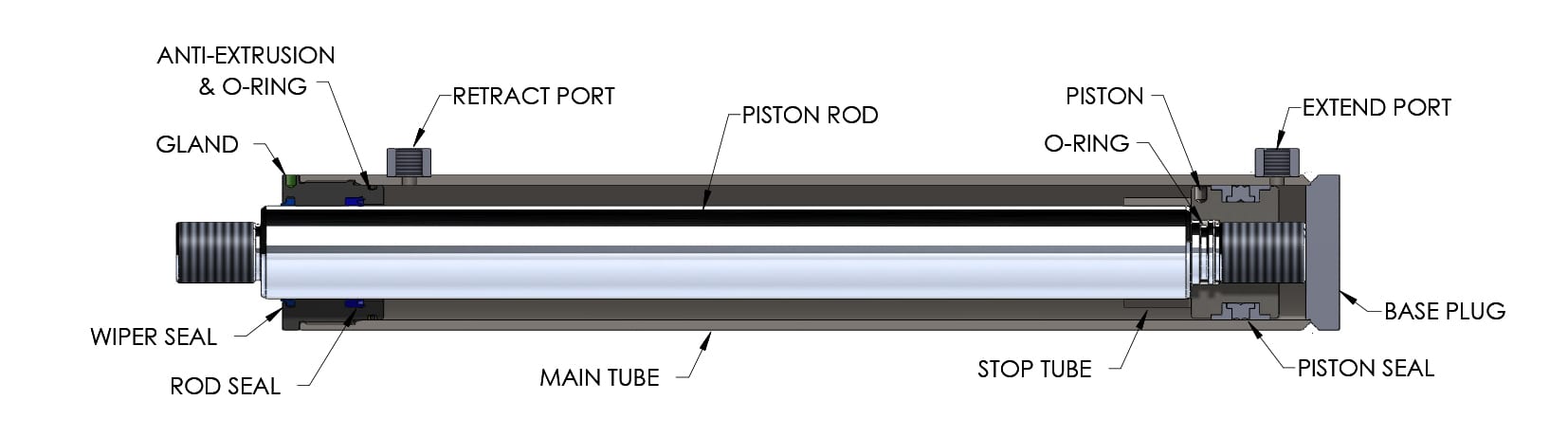

Hydraulic cylinders are linear actuators that convert hydraulic fluid power into straight line motion and force. They consist of a base plug, main tube, piston, piston rod, gland and ports. They come in all shapes and forms with differences in design and manufacture varying dependent upon industry and application. There are benefits and disadvantages to each type of cylinder and each construction method uses a different methodology relating to how the end caps are attached to the cylinder tubes. The three most popular types of cylinder construction are welded, tie rod and mill type, all available as either double acting or single acting.

ANATOMY OF A CYLINDER

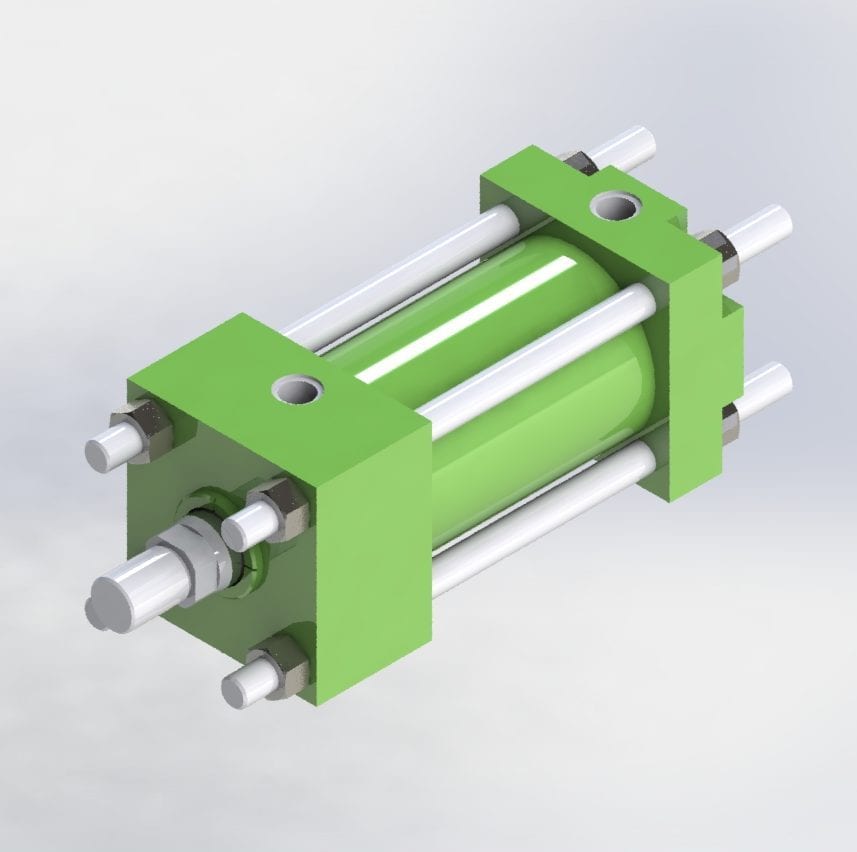

Please see examples of some of the Hydraulic Cylinders that Valley Hydraulics Ltd can offer below. Can’t see what you are looking for? Don’t worry. This is just a small selection of our capabilities – please contact us to discuss your requirements further.

Construction Methods

Welded

This is the most common method of constructing hydraulic cylinders with the majority of cylinders supplied by Valley hydraulics falling within this arrangement. A welded hydraulic cylinder is made up of a base plug welded to one end of the main cylinder tube and a gland or end cap is screwed into the opposite end, this allows the piston rod assembly to be removed for servicing. The weld around the base plug seals one end of the tube whilst at the other end the gland includes a range of seals to seal both the tube and the piston rod.

Benefits

- The most cost effective construction method

- Compact construction

- Good bearing lengths achieved

- Aesthetically simple, they blend into and can enhance the look of the equipment to which they are installed

- Reliable

Disadvantages

- Out in the field more difficult to repair/maintain

- Can be more costly to repair should the tube assembly be damaged

Tie Rod

Tie rod hydraulic cylinders differ from other construction methods by using threaded tie rods the same length as the cylinder body to hold the base plug and end cap to either end of the main tube. The cylinders have a base plug fitted with seals to seal one end of tube and an end cap is fitted to the other end with a range of seals to seal against the tube and the piston rod. Each end plug/cap has a series of holes drilled through into which the threaded tie rods are fitted. The threaded rods are then torqued to a specific value either using nuts or screwed directly into one of the end plugs/caps and this holds the cylinder assembly together.

Benefits

- Capable of withstanding impact and shock loads so used in heavy duty applications

- Easy to disassemble and examine for repair

- Every component is serviceable, accessible and replaceable

- Cost effective to repair

Disadvantages

- The cylinders are larger than welded construction

- More costly than welded construction

- Limited in terms of design

- Require full disassembly to inspect and service internal components

Mill Type

The end plug and cap in mill type hydraulic cylinders are bolted to flanges that are generally welded to both ends of the main tube. The flanges include an array of holes and both the end plug and cap are offered to a flange on either end of the tube, high strength bolts are then fitted and torqued to a specific value to hold the end cap and plug in place. The end plug includes seals to seal one end of the tube and the end cap includes an arrangement of seals to seal against the tube and piston rod.

Benefits

- Heavy duty robust in design

- Good for shock loading applications

- The most serviceable as each end of the cylinder can be accessed by unbolting one end cap

Disadvantages

- Costly construction method

- The cylinders are larger than welded construction

- Limited in terms of design

Hydraulic Cylinder Types

Single Acting

Have only one oil inlet port to either extend or retract the hydraulic cylinder using hydraulic power, once full stroke is hit the movement to return the cylinder to its start position is usually achieved by using the load lifted, gravity or a spring. An additional port is usually added on the non-oil side of the tube, this allows the hydraulic cylinder to breathe air in and out as it is extended or retracted. Usually this port would be fitted with either a breather or a hose that would connect this area to the hydraulic tank, this is to reduce corrosion issues caused by moist air being drawn in and out of the cylinder tube.

Double Acting

Having an oil inlet port at either side of the piston seal allows a double acting hydraulic cylinder to be extended and retracted using hydraulic power. This type of cylinder is usually used where an external force is not available to return the cylinder to its starting position or where a force is required in both directions.

Displacement

Displacement hydraulic cylinders are single acting extension only cylinders that are retracted using the load lifted and gravity. The cylinder is initially filled with hydraulic fluid in the area surrounding the piston rod when in its fully retracted state, when more fluid is then pumped into the cylinder it will displace the volume of the piston rod therefore forcing the piston rod to extend from the tube. The biggest difference between displacement and single acting cylinders is that unlike single acting cylinders there is no piston seal in a displacement cylinder. This means the force generated by a displacement cylinder is less than the force generated by a single acting cylinder of the same size as the force is calculated based on the area of the piston rod and not on the tube bore as it is for single acting cylinders. However, the displacement cylinder does remove the corrosion issues associated with single acting cylinders as no air breather is required.

Through Rod

As the name suggests with this type of hydraulic cylinder there is no full bore, the piston rod extends through and out of both sides of the main cylinder tube. The piston is situated in the middle of the piston rod and there is a port at either end of the main tube to operate the piston rod in both directions. So when operated the piston rod will extend out of one end of the tube and retract into the other end, then vice versa when operated in the opposite direction. This type of cylinder is ideal for vehicle steering applications.

Telescopic

A telescopic hydraulic cylinder has a number of sections of steel tubes with successively smaller diameters that nest inside each other. This results in a small compact hydraulic cylinder when in its retracted state that offers a long length of travel when extended. Telescopic cylinders usually extend from the largest stage to the smallest, this means that the largest stage with all the other sections nested inside will generally move first and complete its stroke before the next section moves. This will continue through all sections until the smallest section completes its stroke. The opposite can be said when the cylinder is retracting, the smallest section will fully retract before the next section moves and this will continue until all sections are fully retracted and nested back inside the main tube. Telescopic cylinders can be supplied as single acting/double acting or displacement types.

Synchronised Telescopic

Synchronised telescopic hydraulic cylinders look and operate much the same as a telescopic hydraulic cylinder but with one major difference, all of the stages extend or retract at the same time. When the cylinder is in its fully closed state oil is trapped in the annulus area of all stages except the smallest stage. As oil is introduced to the full bore of the largest stage the piston rod on this stage begins to extend, this transfers the oil trapped in the annulus area of the largest stage into the full bore of the next stage. The transfer of oil causes the piston rod on the next stage to extend so that both piston rods are extending at the same time. This same principle occurs through all stages so that all piston rods are extending at the same time. In retraction it all works in reverse, so oil is introduced into the annulus of the smallest stage to retract the piston rod which transfers oil from the full bore of this stage to the annulus of the next stage up in size and so on so that all piston rods retract together. This means the cylinders maintain a constant speed whilst extending or retracting unlike the standard telescopic cylinders which change speed with each change in section.

Master/Slave

With this configuration one cylinder, the master cylinder, is used to drive a number of slave cylinders in sequence, the result is from only one input a number of cylinders will extend and retract simultaneously. This all works by matching annulus to full bore volumes and transferring oil from one cylinder to the next. A hydraulic service line is connected to the full bore of the master cylinder, the rod side of the master cylinder is connected to the full bore of slave cylinder number 1, the rod side of slave cylinder number 1 is then connected to the full bore of slave cylinder number 2 and so on until the last cylinder in the sequence is reached where the rod side is connected back to tank. All cylinders are then primed using internal valves so that every cylinder is in its fully retracted state with the annulus areas filled with trapped oil. The volume of oil in the rod side of each cylinder is identically matched to the volume of oil required to extend the full bore of the next cylinder in the sequence. This means when the master cylinder is extended the dormant trapped oil in the rod side of each cylinder is transferred to the full bore of the next cylinder in the sequence which extends the next cylinder, therefore all cylinders extend together. The cylinders also retract together when oil is sent to the annulus of the last cylinder in sequence, this transfers all of the dormant trapped oil in the full bore of each cylinder back to the rod side of the next cylinder in sequence, therefore retracting all cylinders from a single input.